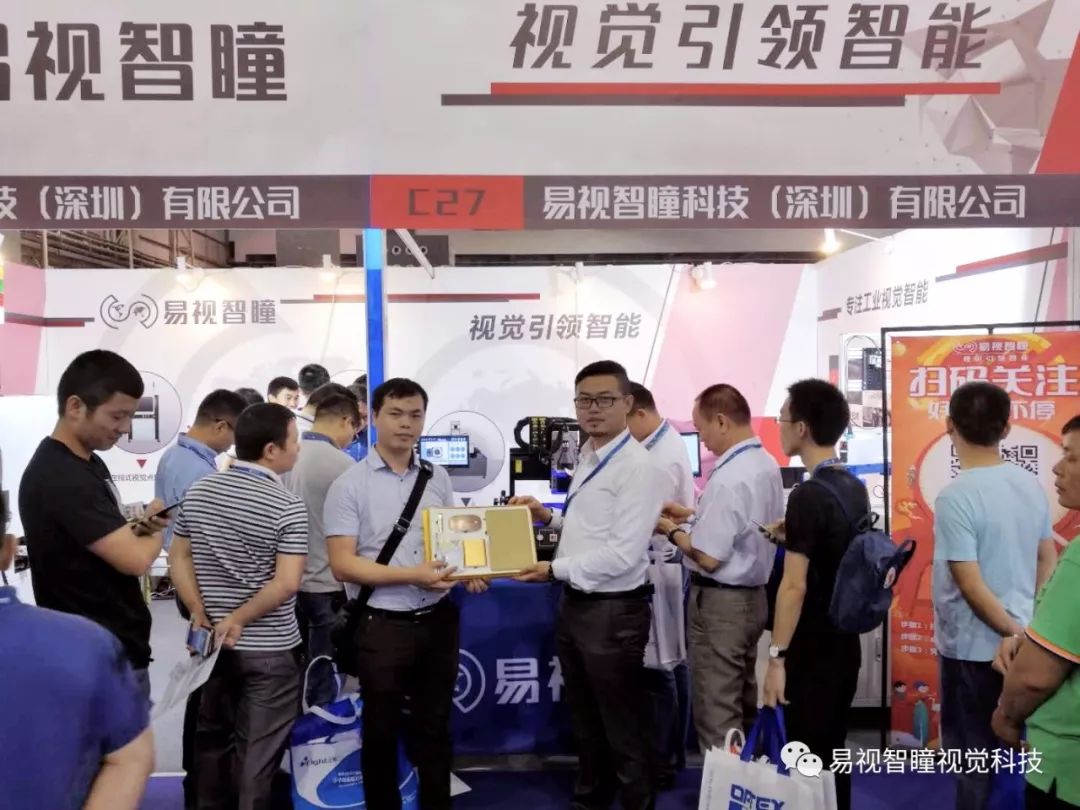

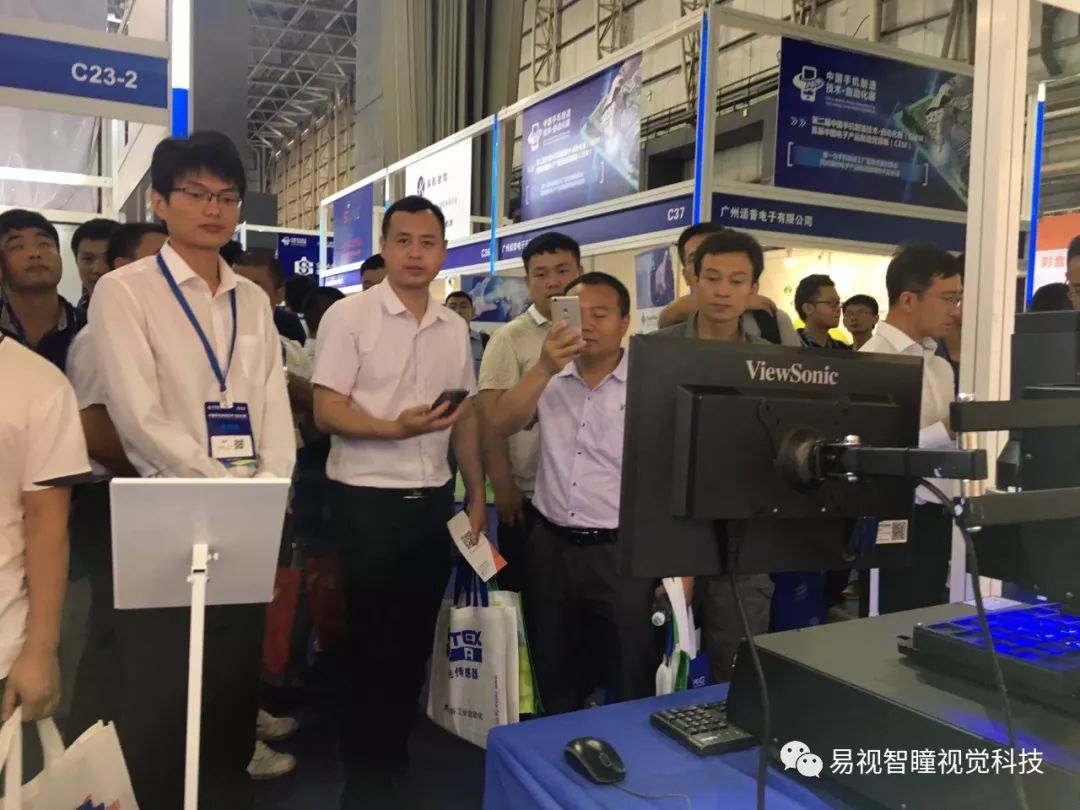

On May 16-17, 2018, Esight Techonology Technology and more than 300 upstream and downstream system, equipment and solution providers in the mobile phone manufacturing industry chain appeared at the 2nd China Mobile Phone Manufacturing Technology Automation Exhibition (CMM). 2 days of industrial feast.

In recent years, the mobile phone manufacturing industry has faced tremendous pressure from the 'Industry 4.0' industrial upgrading, and at the same time, it is also facing the challenges of the gradual slowdown in global mobile phone sales growth and the continuous increase in mobile phone manufacturing costs. Building 'smart manufacturing' and 'smart factory' has become the consensus of many upstream and downstream enterprises in mobile phone manufacturing, processing, and design.

As the only exhibition tailored for mobile phone manufacturing factories, this exhibition brings together the widest range of mobile phone manufacturing automation equipment suppliers, manufacturers, integrators, and solution providers, and is committed to providing a new generation of 'smart manufacturing' enterprises with an Professional communication platform. For the mobile phone manufacturing industry, a large number of cutting-edge new technologies and new products of electronic production equipment such as automatic dispensing machines, robotic flexible production lines, and automatic motherboard testing were exhibited, attracting more than 6,000 industry professional visitors.

From analysis to testing, from assembly to warehousing, change all manual processes; from equipment to appliances, from software to systems, comprehensively upgrade Chinese mobile phone factories; follow the trend of intelligent manufacturing, lead the transformation of the mobile phone manufacturing industry, and showcase the cutting-edge achievements of global electronics manufacturing automation.

Esight Techonology Technology focuses on industrial visual intelligence technology, based on its own core visual algorithms, combined with years of process accumulation, to create professional and efficient industrial vision systems and solutions for intelligent manufacturing enterprises. At this exhibition, Esight Techonology will bring a high-precision visual dispensing system, a high-precision dimension measurement and detection system, and a robotic arm vision guidance system.

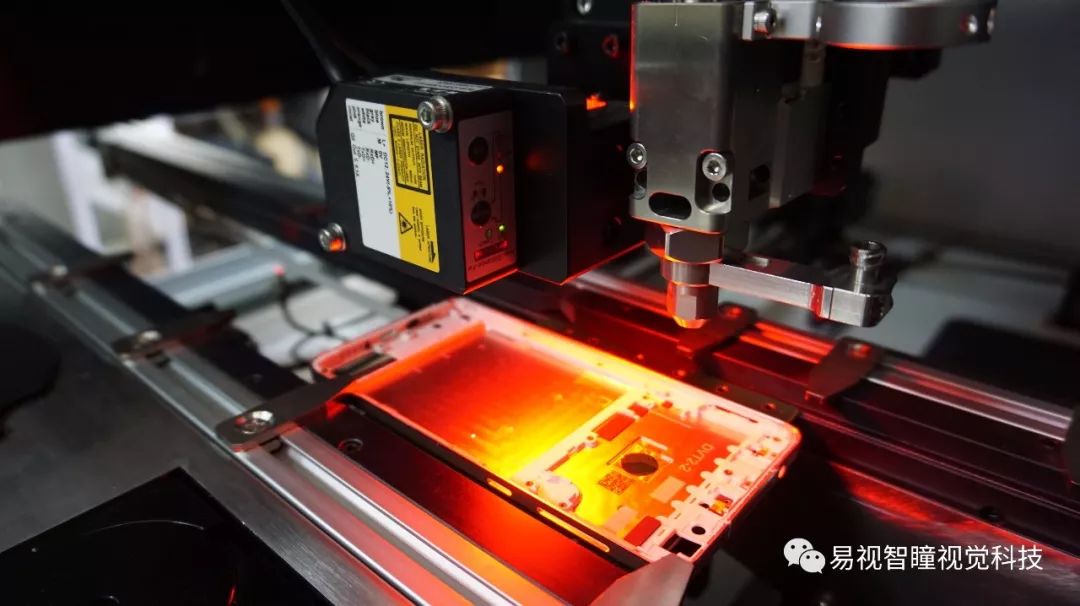

High Precision Vision Dispensing System

The high-precision visual dispensing system integrates the functions of visual perception, motion control and dispensing technology of the dispensing process, which facilitates the integration of various actuators and forms terminal dispensing products in one step to meet the dispensing needs of various production lines.

Product advantages

Own core algorithm

Support multi-axis linkage

Ontology recognition function

Application scenarios

It is used in the dispensing scene of high-precision electronic products such as mobile phone cameras, fingerprint modules, and mobile phone middle frames.

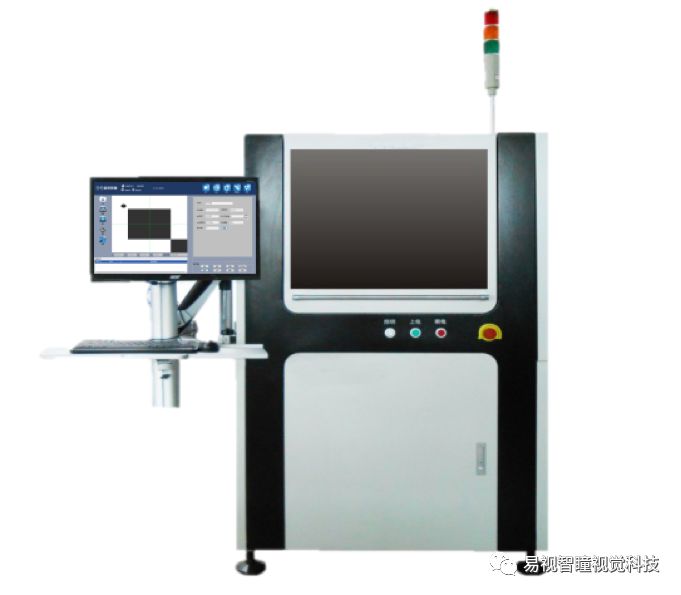

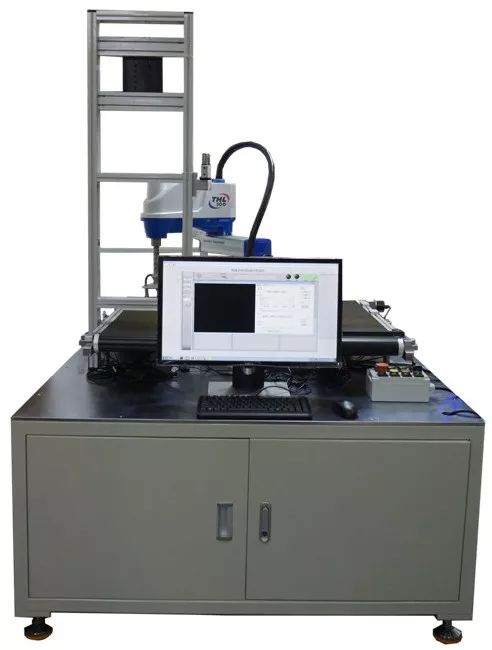

High-precision dimensional measurement and inspection system

High-precision visual dimensional measurement and inspection series, based on machine vision distance, non-contact accurate measurement and online inspection of workpieces.

Product advantages

High precision, easy operation and strong adaptability

Support template matching, automatic positioning

Average single workpiece detection time 3-5s

One-click batch measurement with ease

Application scenarios

It is suitable for small workpiece size inspection and full production line inspection in the fields of machinery, electronics and hardware, especially for mass production scenarios with high precision requirements.

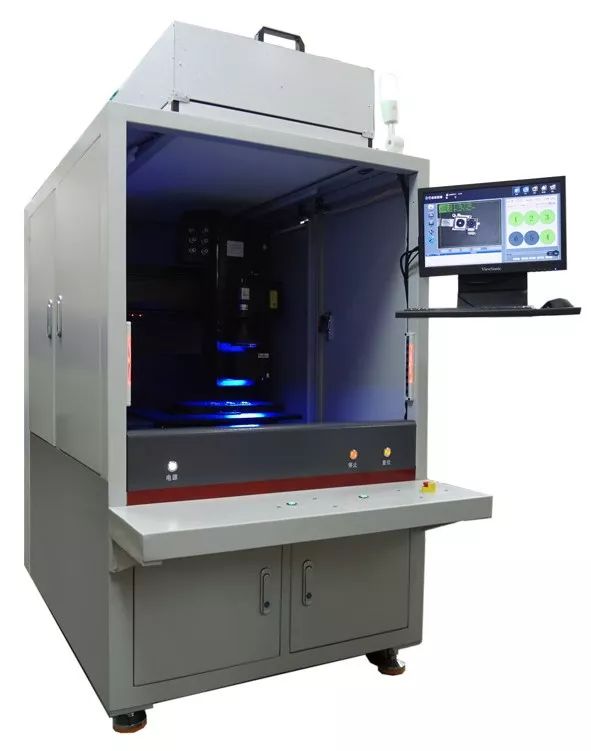

Robotic arm vision guidance system

The robotic arm vision guidance system fully considers the complex materials, various types and high precision requirements, and provides a high-speed, high-precision and cost-effective automatic gluing solution.

Product advantages

3D trajectory planning, stable operation effect

One-key calibration function, fast production and import

Reduce manual participation and greatly improve efficiency

On-site raffle winners

At the exhibition site, Esight Techonology provided a wealth of on-site sign-in prizes to thank the audience for their support. The audience responded enthusiastically in the lottery session. 5 lucky friends won the first prize of a luxury business gift box. The list of winners is as follows:

Shenzhen Flat Panel Display Industry Association Liu Rixia

Shanghai Haiyou Frequency Radio Technology Co., Ltd. Chen Hao

Shenzhen Rongxinxiang Automation Co., Ltd. Feng Xiaotie

Shenzhen Rongxinxiang Automation Co., Ltd. Longshule

Dongguan Yuanyao Electronic Technology Co., Ltd. Wu Heng