On October 11-12, the Smart Manufacturing Summit - Smart Manufacturing Congress--A.I. and Robotics, hosted by the Hong Kong Productivity Council and the Hong Kong Innovation and Technology Commission, was grandly held in the Hong Kong Productivity Council Building. The three-day Smart Manufacturing Summit brings together distinguished guests from around the world in the field of artificial intelligence and industrial robots.

Intelligent manufacturing is an important direction for national industry and even global development. It can not only bring Hong Kong's industry to a higher level, but also lead the industrial upgrading of the Guangdong-Hong Kong-Macao Greater Bay Area. In order to promote the application of smart manufacturing technology, the Hong Kong Productivity Council held the Smart Manufacturing Summit, inviting international authorities and industry leaders from different regions, focusing on intelligent automation and robotics, to analyze incisive insights through speeches, discussing technology applications and field visits. Enhancing the innovation capabilities of the manufacturing industry in Hong Kong and the Greater Bay Area will benefit the development of the industry.

As an area connecting the 'Belt and Road' and the international market, the 'Guangdong-Hong Kong-Macao Greater Bay Area' plan is on the horizon, and industrial upgrading is imperative; however, the recent international trade frictions have continued to heat up, making the business environment of the Greater Bay Area even stronger. variable. Facing the challenges that follow, many advanced countries around the world are striving to seize the opportunity of 're-industrialization' as an important development strategy to promote economic growth, allowing industry to support the development of the real economy. In recent years, the Hong Kong SAR government has vigorously promoted relevant policies and allocated tens of billions of resources to promote the process of local 're-industrialization'.

Guests who participated in the keynote speeches of the conference included Professor Ni Jun from the Department of Mechanical Engineering of the University of Michigan, Director of Wu Xianming Manufacturing Center, Distinguished Chair Professor of the University of Cincinnati, and National Science Foundation (NSF) Intelligent Maintenance System Industry-University Cooperation Center (IMS) , Industrial Artificial Intelligence Center, Professor Li Jie, Senior Consultant of McKinsey & Company and Foxconn Group Co., Ltd., Academician of the Chinese Academy of Engineering, Professor Tan Jianrong, Director of the Department of Mechanical Engineering of Zhejiang University, Professor Li Zexiang of the Department of Electronic and Computer Engineering, Hong Kong University of Science and Technology, etc. Esight Techonology Technology and many other well-known enterprises in the field of artificial intelligence industry.

In the forum, Dr. Huang Bufu of Esight Techonology Technology introduced the 'Vision Intelligence Collaboration +' industrial vision intelligent system and technological breakthroughs and application cases independently developed by Yishi Zhitong to the guests. 'Vision Intelligence +' is equivalent to the eyes, brain and cerebellum of industrial robots. Based on its own vision control technology, intelligent and efficient software architecture and deeply optimized hardware system, Easy Vision Smart Pupil vertically integrates the three core technologies of machine vision, deep learning and collaborative operation control, and can be quickly imported and controlled with industrial actuators , so as to provide low-cost, high-quality and high-efficiency solutions for intelligent manufacturing enterprises. At present, the system has been maturely used in the production lines of first-tier manufacturers in the fields of SMT, 3C, and laser welding.

With its own core visual control technology, Esight Techonology has achieved a major breakthrough in the field of 3D multi-axis curved surface dispensing and lamination technology. 3D multi-axis curved surface dispensing and lamination technology is mainly for the application scenarios of OLED flexible display and 3D curved screen dispensing and lamination. Due to the particularity of the three-dimensional trajectory and the structure of the curved screen, the difficulty of the curved surface lamination process is greatly increased, and the manual lamination cannot guarantee high yield and consistency, resulting in an order of magnitude higher cost. The lack of OLED surface lamination equipment has become one of the bottlenecks in the industry. Esight Techonology is the first to realize 3D multi-axis curved surface dispensing technology, breaking through the international monopoly of this technology and realizing the localization of high-end equipment. At present, it has been applied to the 3D squeegee of first-tier mobile phone manufacturers and the dispensing scene of automobile 3D camera.

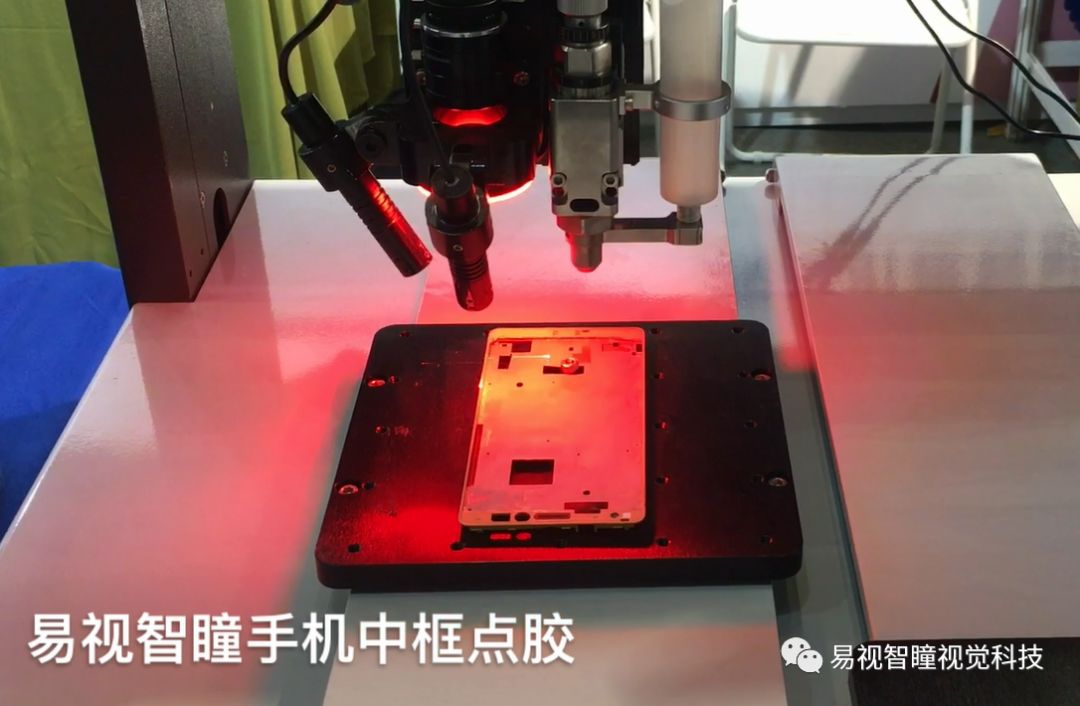

In addition, the 3D edge patrol function of Vision Smart Collaboration + dispensing equipment provides an efficient solution for the application scenario of mobile phone middle frame dispensing. Nowadays, mobile phones and smart hardware with a high screen ratio are the general trend, but at the process level, due to the narrower and narrower bezels, higher requirements are also placed on the dispensing technology of the middle frame of mobile phones. By optimizing the visual algorithm, Esight Techonology can automatically identify the three-dimensional coordinate positioning of the ultra-narrow frame, compensate for product deformation and deviation, achieve a minimum glue width of 0.3mm, and ensure the uniformity and consistency of the glue path.

Subsequently, Dr. Huang Bufu shared with the guests the application of vision-intelligent collaboration + robotic arm in 3C manufacturing scenarios. In the video shown, Eft's SCARA robotic arm is very agile to dispense glue for two different mobile phone middle frames. The device introduces the SCARA robotic arm into the 3C high-precision dispensing scene for the first time to achieve silk-level tracking accuracy. Flexible manufacturing process that can be flexibly applied to in-line mixed production.

Finally, Dr. Huang Bufu believes that machine vision is the best entry point for artificial intelligence and intelligent manufacturing. Esight Techonology Technology aims to achieve vision-led intelligence through 'Vision Intelligence Collaboration +' and help the development process of my country's intelligent manufacturing.