The annual 2019 ACT Smart Technology and Application Conference was grandly held in Jinji Lake, Suzhou on June 21, 2019. More than 2,000 industry technical elites enthusiastically attended the conference to inspire their thinking and inspire their wisdom. The SMT China step-by-step technical seminar-Suzhou conference has three parallel sessions with the themes of 'Special Process Application Technology and Standards for Third-Order Products', 'Modernization Transformation and Upgrading Plan for Smart Factory', and 'Advanced Technology and Reliability Improvement Plan'. The forum is running simultaneously.

Esight Techonology was invited to participate in this industry technology event, focusing on the new 3D precision dispensing process in the 5G era, discussing the special process application technology and standards of third-order products, new ideas for modern transformation and upgrading of smart factories, and discussing the future of SMT smart manufacturing. received the attention of the industry.

5G will greatly stimulate the development of the consumer electronics terminal industry, bring a new wave of smartphone replacements, and promote the development of new technologies such as mobile phone antennas, middle frames, and batteries. At the same time, the 5G era has also brought more difficult pain points to the SMT industry: the complex dispensing conditions in the 5G era have put forward new requirements for the yield and accuracy of the production line; the precision dispensing of surfaces in the 5G era provides 3D positioning Complex operation control brings new challenges; flexible precision production in the 5G era brings new models of equipment reliability and automation upgrades.

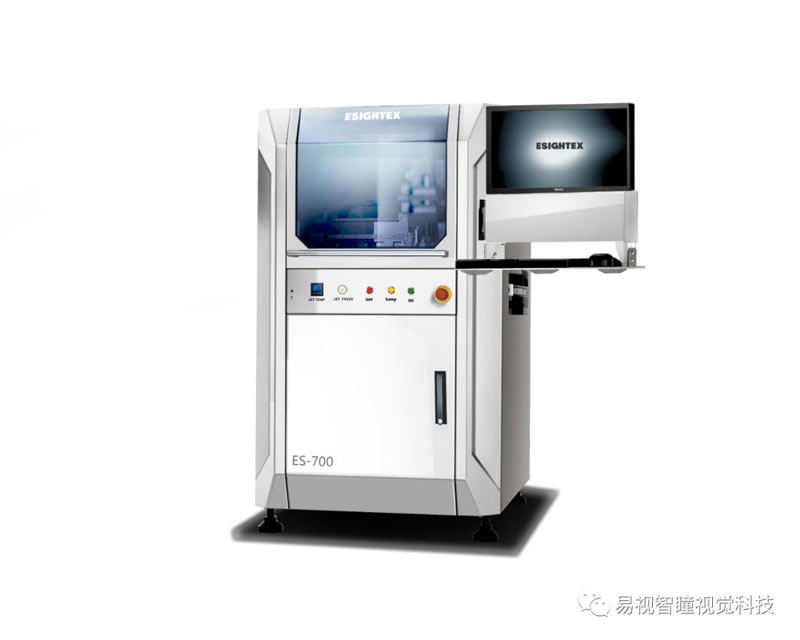

Facing the needs of 3D multi-axis surface lamination technology and new processes in the 5G era, Esight Techonology has independently developed a high-precision 3D edge inspection visual dispensing machine, using 3D + 2D visual positioning, combined with multi-axis linkage dispensing, making glue The head is perpendicular to the target, and it is used in the dispensing scene of high-precision electronic products such as mobile phone cameras, fingerprint modules, and mobile phone middle frames. It takes the lead in realizing the 3D surface dispensing process in China, which mainly solves the poor dispensing caused by the target height and product deformation during the filling and dispensing of the middle frame of the mobile phone, the screen of the mobile phone, and the back cover of the mobile phone, and ensures the consistency of the dispensing path. At present, it has solved the process problems of 3D curved screen lamination, mobile phone narrow frame dispensing, mobile phone battery filling and other process problems for many domestic first-line mobile phone manufacturers and intelligent hardware manufacturers, while ensuring the dispensing accuracy, and achieving high stability It can meet the dispensing needs of various production lines and greatly improve the yield and production efficiency.

【About Esight Techonology】

Esight Techonology (Shenzhen) Co., Ltd. was established in 2015 by the high-level outstanding talents of Peacock overseas, combined with overseas experts and senior technical and management personnel from the top 100 Shenzhen enterprises. Focus on industrial visual intelligence technology, with machine vision and deep learning as the core, to create the core platform technology of 'Visual Intelligence Collaboration +', to realize the visual perception and execution decision-making of industrial robots, and to realize the intelligent technology in the field of industrial Internet and intelligent manufacturing, The localization of industrial software and high-end equipment has helped China enter the era of intelligent manufacturing led by machine vision.